Views: 0 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

Impact Damage: External corners in high-traffic areas are prone to dents, chips, and deformation from furniture, equipment, or accidental contact

Joint Cracking: Drywall joints often develop hairline cracks due to building settlement, temperature fluctuations, or inadequate reinforcement

Moisture Penetration: Bathrooms, kitchens, and basements expose corners to humidity, leading to material degradation and mold growth

Time-Consuming Repairs: Traditional corner protection methods require multiple steps, specialized tools, and extended drying times

Aesthetic Compromises: Uneven finishes and visible seams detract from the professional appearance of interior spaces

Surface Cleaning: Remove dust, debris, and grease from wall surfaces using a damp cloth or vacuum

Corner Inspection: Check corners for existing damage, unevenness, or protrusions that require correction

Moisture Assessment: Ensure surfaces are completely dry, especially in bathrooms and basements

Tool Gathering: Prepare necessary tools including utility knife, measuring tape, level, and smoothing tools

Measure the corner length and mark the PVC corner bead accordingly

Use a utility knife or fine-tooth saw for clean, straight cuts

For outside corners, cut at 45-degree angles for seamless joins

Apply construction adhesive evenly along the back of the corner bead

For additional security, use galvanized nails or screws at 12-inch intervals

Ensure the bead sits flush against the corner without gaps

Apply joint compound over the corner bead, feathering edges smoothly

Allow to dry completely before sanding and applying additional coats

Final sanding should create a seamless transition to adjacent walls

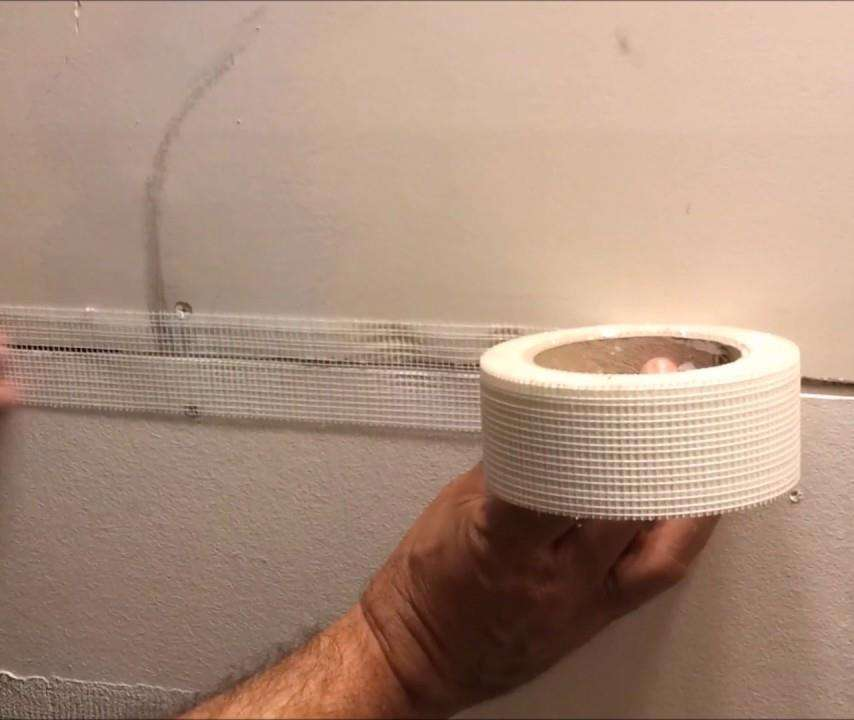

Ensure drywall joints are clean, dry, and free of loose material

Apply a thin layer of joint compound to the joint area

Cut the self-adhesive fiberglass tape to the required length

Peel the backing paper and press the tape firmly into the joint compound

Ensure full contact along the entire length, smoothing out air bubbles

Apply a second layer of joint compound over the tape, embedding it completely

Feather edges to create a smooth, gradual transition

Allow to dry, sand lightly, and apply final finish coats

Temperature Considerations: Install at temperatures between 50-90°F (10-32°C) for optimal adhesion

Humidity Control: Avoid installation in extremely humid conditions that can affect drying times

Overlap Technique: When joining tape sections, overlap by at least 2 inches for continuous reinforcement

Feathering Technique: Always feather joint compound edges to prevent visible ridges

Safety Measures: Wear protective gloves and eye protection during cutting and installation